ASTER case erectors, stand alone or in line with loading and case closing modules

ASTERON mono block RSC case packer: case erector, products loading, case closing

ATOMAX wrap around cardboard packaging solutions

VORTEX tray formers

COMBY PACK packaging line: tray former with cups loading module

SLEEVEE machine for cardboard envelope application

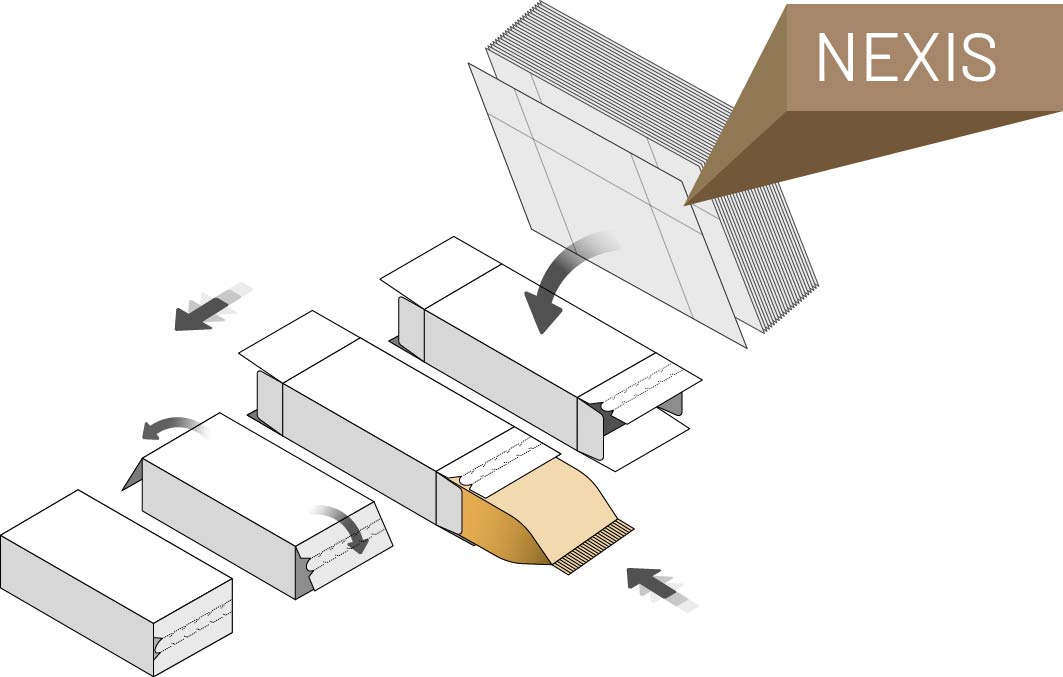

NEXIS side load cardboard packaging systems for single or multiple products

PALLETIZATION of various characteristics and capacities

ROBOTIC integrations

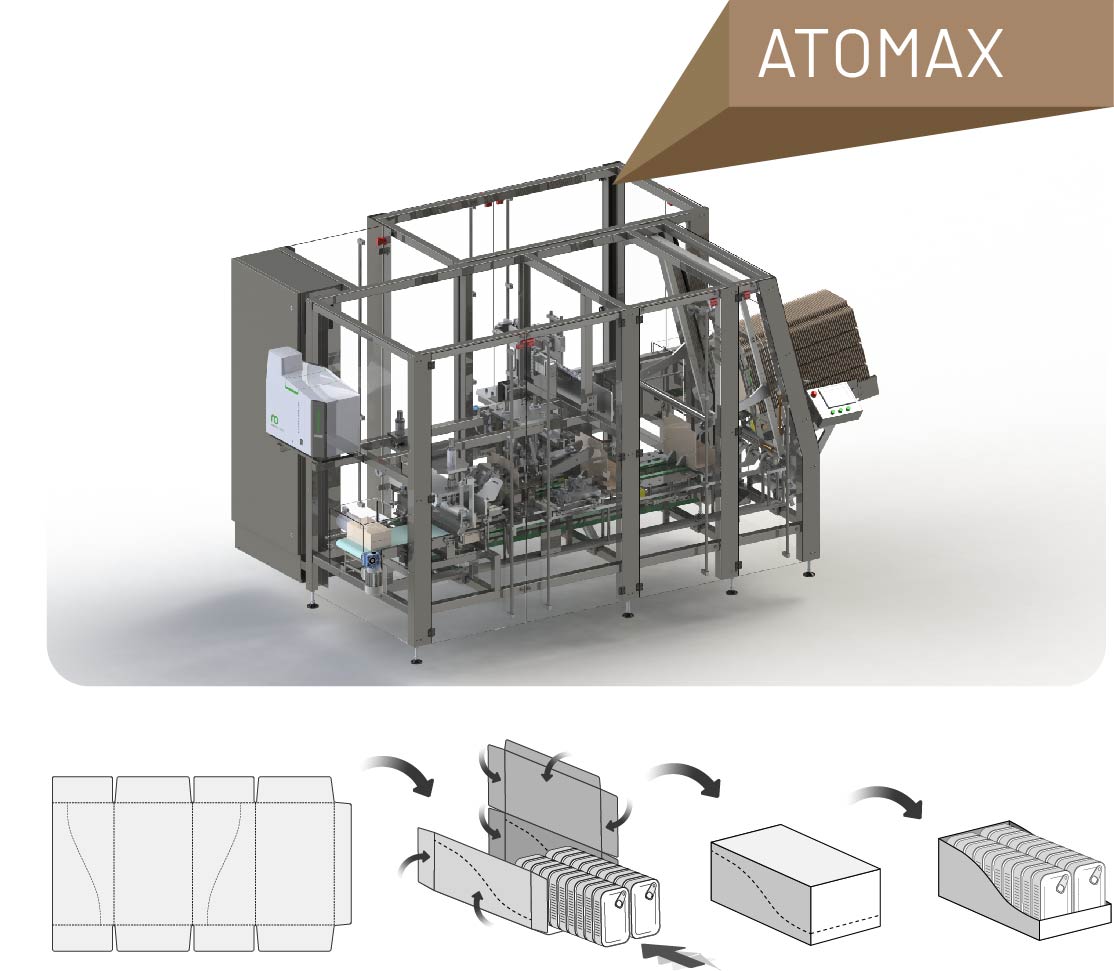

ATOMAX is presented as a family of wrap around case packers: full wrap around, open tray wraps around solution or double case loading solution - all designed and produced for different applications in industries.

Machinex wrap around case packers, ATOMAX, are designed for demanding working regime in dairy, meat, chemical and other production facilities in 24/7 working hours.

ATOMAX wrap around system is created as automatic case packer: to form the case, prepare products for loading, folding and sealing case's flaps around group of loaded products. Operates automatically based on electronic controls and installed programs. Hi-speed solutions are driven by servo motors to achieve maximum capacities.

Case type: flat preformed cardboard blank.

Case sealing: hot melt.

ATOMAX is indexing motion case packer. Manually adjustable for different case's dimensions in 20 minutes, tool free. Automatic change over upon request.

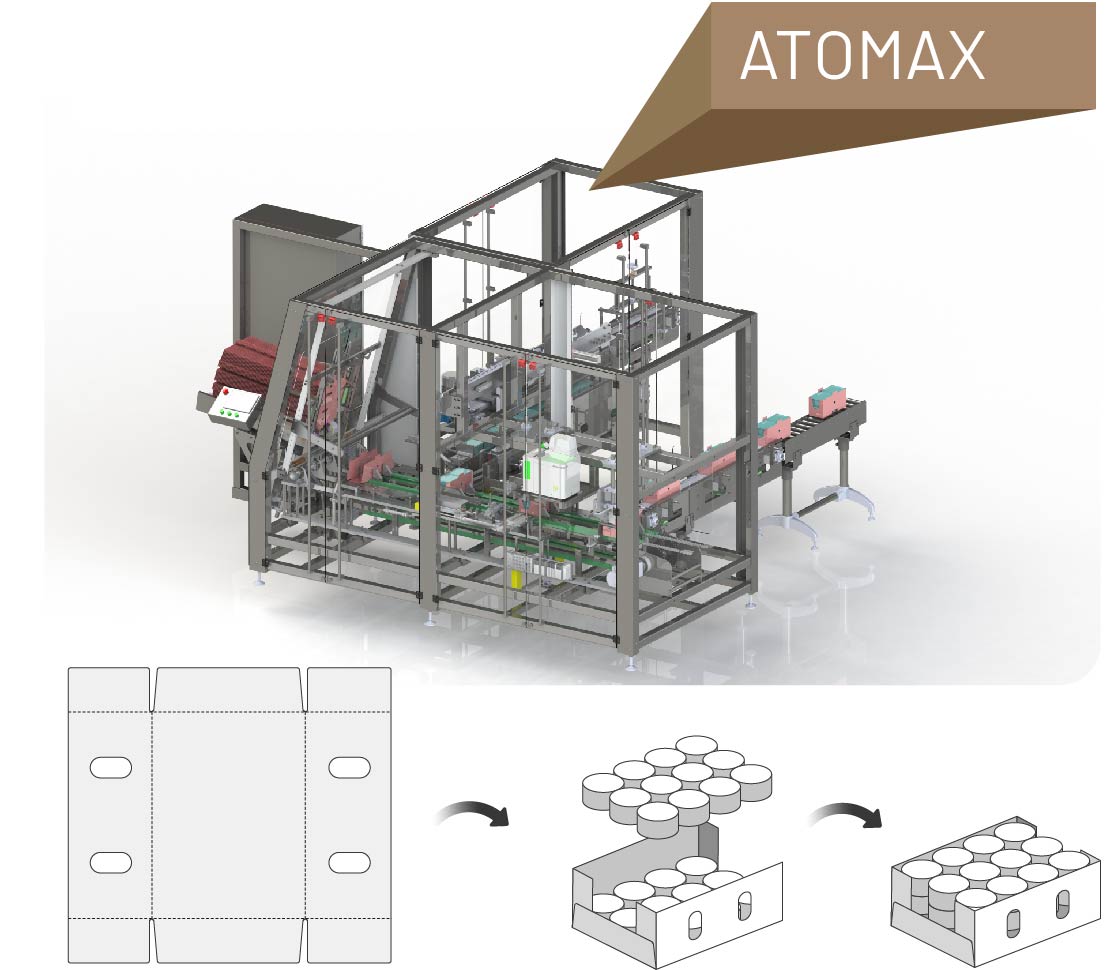

ATOMAX OPEN TRAY is designed as wrap around case packer for some self- supporting products, which can be palletized without cover part of the case.

This is a fully automated wrap around case packer providing packaging in open tray type case. It is possible to have on one machine two types of cases: open tray and fully closed box. Machinex wrap around case packers, ATOMAX, are designed for demanding working regime in dairy, meat, chemical and other production facilities in 24/7 working hours.

ATOMAX wrap around system is created as automatic case packer: to form the case, prepare products for loading, folding and sealing case's flaps around group of loaded products. Operates automatically based on electronic controls and installed programs. Hi-speed solutions are driven by servo motors to achieve maximum capacities.

Case type: flat preformed cardboard blank.

Case sealing: hot melt.

ATOMAX is indexing motion case packer. Manually adjustable for different case's dimensions in 20 minutes, tool free. Automatic change over upon request.

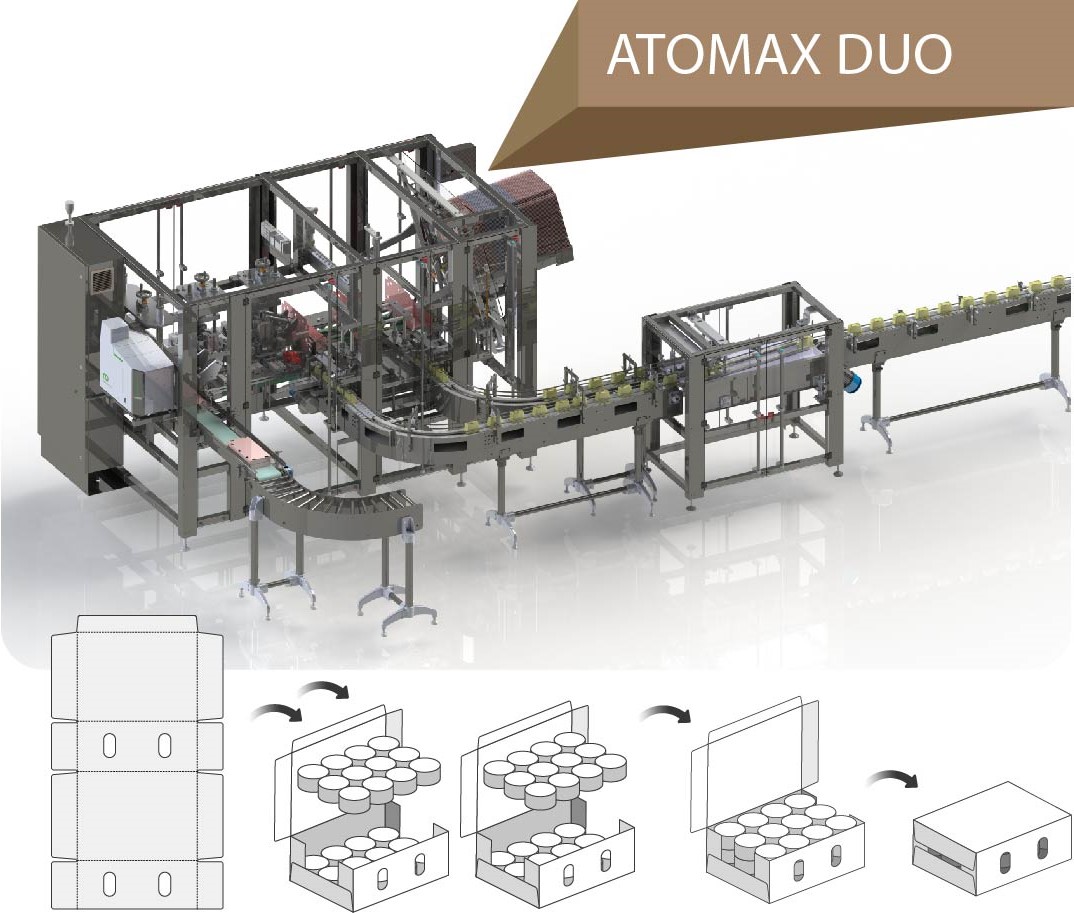

ATOMAX DUO is indexing hi speed wrap around case packer. This is a fully automated wrap around case packer providing packaging up to 20 cases per minute by loading 2 cases simultaneously.

By dividing incoming flow of products on two preparing and loading positions and loading two cases at the same time, closing one by one with hot melt, Machinex offers a very optimal and suitable packaging solution.

ATOMAX DUO, Machinex hi speed wrap around case packers, are designed for demanding working regime in dairy, meat, chemical and other production facilities in 24/7 working hours.

ATOMAX DUO, wrap around system, operates automatically based on electronic controls and installed programs, driven by servo motors to achieve maximum capacity.

Case type: flat preformed cardboard blank.

Case sealing: hot melt.

ATOMAX is indexing motion case packer. Manually adjustable for different case’s dimensions in 20 minutes, tool free.

Automatic change over upon request.

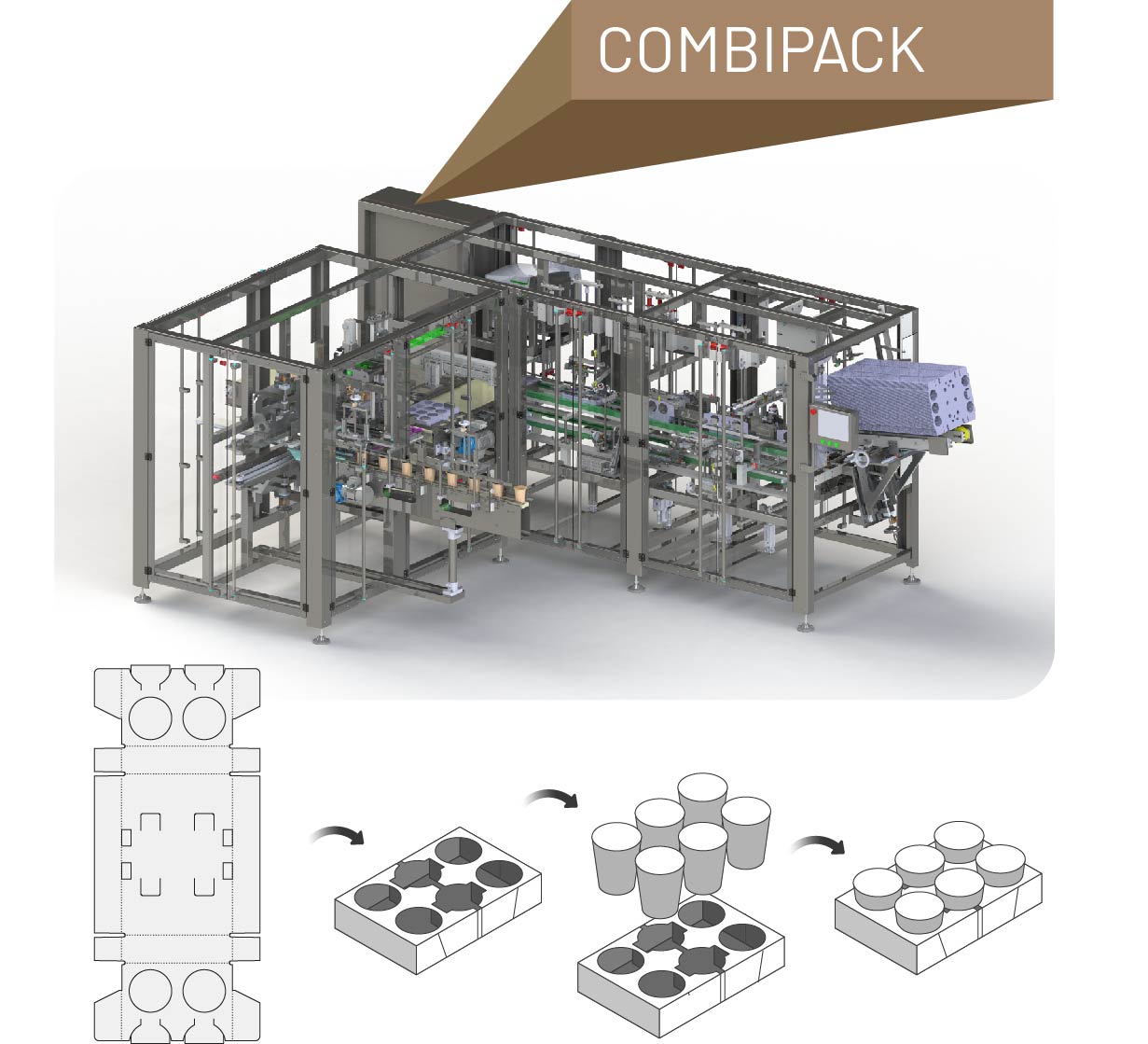

Loading module is equipped with robotic hand to pick complete formation of incoming cups and transfer group into the prepared tray. End-of-arm is designed according specific characteristics of cups and can be with vacuum suction cups or fingers for safe transfer.

COMBIPACK configurations:COMBYPACK can be delivered as Single format or Multi format - a solution with exchangeable format tooling.

Format change over can be applied on either one or both modules. Combined servo-pneumatic system - an optimised solution for a maximum speed of 22 trays per minute and an adequate cups for loading.

High-speed full servo system - max capacity of up to 40 trays per minute. All manipulations are performed by servo drives.

In any case, NEXIS systems have a simple and accessible design, which greatly facilitates use and maintenance over a long period of use.

NEXIS can be adjustable for different cases or product/s dimensions.

Format change: manual, with rulers and counters for precise positioning.

Format change-over time up to 20 minutes.